1. Definition

What is a Vaccine/Medication Refrigerator?

A vaccine or medication refrigerator is a specialized medical-grade cooling appliance designed to store temperature-sensitive pharmaceuticals, biologics, and vaccines within a precise, stable, and uniform temperature range, typically between +2°C and +8°C. Unlike standard household refrigerators, these devices are engineered with advanced temperature control, monitoring, and air circulation systems to ensure the potency, efficacy, and safety of their contents. Their primary function is to serve as a critical link in the “cold chain”—the uninterrupted series of refrigerated production, storage, and distribution activities—for vital medical products.

How it Works

At its core, a vaccine refrigerator works on the same vapor-compression cycle as a domestic fridge but with far greater precision. A refrigerant gas is compressed, becomes hot, and is cooled in a condenser to become a liquid. This liquid then passes through an expansion valve, turning into a cold, low-pressure gas that absorbs heat from the refrigerator’s interior via an evaporator. A fan then circulates this cold air evenly throughout the cabinet. The key differentiator is the sophisticated control system. A digital microprocessor continuously monitors temperatures via multiple sensors. It makes minute adjustments to the compressor and fan speeds to maintain temperature stability within a tight tolerance (often ±0.5°C to ±1°C), preventing the harmful temperature fluctuations that can degrade medications.

Key Components

- Compressor: The heart of the cooling system. Medical-grade models often use heavy-duty, long-life compressors designed for continuous operation.

- Microprocessor-Based Controller: The “brain.” It receives input from sensors and regulates the compressor, fans, and any alarms.

- Temperature Sensors & Probes: Strategically placed (often in a glycol or buffer solution to mimic vaccine temperature) to accurately monitor internal air and product temperature.

- Interior Circulation Fan: Ensures uniform air distribution, eliminating warm and cold spots.

- Thermal Insulation: High-density foam insulation maintains temperature stability and efficiency.

- Door & Gasket: Feature tight-sealing, robust gaskets and often auto-close mechanisms to minimize temperature loss. Glass doors are typically double or triple-paned.

- Alarm System: Audible and visual alarms for door-ajar, high/low temperature, power failure, and sensor failure. Many feature battery backup for alarms.

- Data Logger/Display: A digital display shows current and setpoint temperatures. Many models have built-in data loggers to record temperature history for compliance.

- Interior Shelving: Durable, wire-style shelves that allow for optimal air circulation around products. Some are adjustable.

2. Uses

Clinical Applications

These refrigerators are indispensable for storing a wide array of temperature-sensitive medical products:

- Vaccines: For routine immunization programs (MMR, Varicella, HPV) and critical supplies (COVID-19 mRNA vaccines, which have specific ultra-cold and refrigerated storage phases).

- Insulin and Other Hormones: Essential for diabetes management.

- Biologics: Monoclonal antibodies, blood products (like albumin), and other complex drugs derived from living organisms.

- Chemotherapy Drugs: Many cytotoxic agents require refrigerated storage.

- Diagnostic Reagents: Used in laboratory testing.

- Ophthalmic Solutions and Injectable Medications.

Who Uses It

- Pharmacists (Hospital & Retail)

- Nurses (Clinics, Vaccination Centers)

- Physicians (Private Practices)

- Laboratory Technicians

- Biomedical Engineers / Technicians (responsible for maintenance)

- Public Health Officials (managing immunization programs)

Departments/Settings

- Hospital Pharmacies

- Oncology and Infusion Centers

- Laboratory & Blood Banks

- Inpatient Wards (for point-of-care medications)

- Outpatient Clinics & Doctor’s Offices

- Community Health Centers & Vaccination Hubs

- Research Laboratories

- Dental Practices

- Veterinary Clinics

3. Technical Specs

Typical Specifications

- Temperature Range: +2°C to +8°C (standard), some offer extended ranges (e.g., +1°C to +15°C).

- Temperature Stability: ±0.5°C to ±1.5°C.

- Capacity: Ranges from compact 1.7 cu. ft. (50L) under-counter models to large 25 cu. ft. (700L) pharmacy units.

- Recovery Time: Time to return to setpoint after door opening; typically 5-15 minutes for quality units.

- Power Supply: 115V/60Hz or 230V/50Hz.

- Alarms: Visual (LED) and audible (≥65 dB) for high/low temp, door ajar, power loss, system failure.

- Data Management: USB download, Ethernet/Wi-Fi for remote monitoring, cloud connectivity.

Variants & Sizes

- Compact/Under-Counter: (1.7 – 4.5 cu. ft.) For small clinics or offices.

- Standalone/Standard: (5 – 15 cu. ft.) The most common type for pharmacies and medium-sized clinics.

- Large Capacity/Pharmacy: (15 – 25+ cu. ft.) For central hospital pharmacies or large-scale vaccination programs.

- Explosion-Proof: For storage of flammable substances.

- Passively Cooled (Solar/Direct Drive): For off-grid locations in global health programs.

Materials & Features

- Construction: Exterior is typically powder-coated steel. Interior is easy-clean stainless steel or durable plastic.

- Shelving: Reinforced, fully adjustable wire shelves.

- Doors: Solid or glass, with magnetic gaskets. Locking doors are a critical feature for controlled substances.

- Cycling vs. Fan-Assisted: Modern units are fan-assisted (forced air circulation) for better uniformity.

- Innovations: Remote temperature monitoring via SMS/email, Vaccine Vial Monitors (VVM) status indicators (dedicated lighting), dual-compartment units with separate controls, 22-hour battery backup systems.

Models (Notable Examples)

- Helmer Scientific: i.Series, Horizon Series

- PHCbi (Panasonic): VIP series, MPR series

- Dometic: Medilite, MediCool

- Thermo Fisher Scientific: Forma Pharmacy Refrigerators

- Vestfrost Solutions: Medical Guard series

4. Benefits & Risks

Advantages

- Ensures Product Efficacy: Maintains the chemical and biological stability of life-saving products.

- Regulatory Compliance: Helps facilities meet stringent guidelines from WHO, CDC, FDA, and other bodies.

- Prevents Financial Loss: Protects expensive inventory from spoilage.

- Enhanced Safety: Locking doors secure controlled substances; alarms prevent undetected failures.

- Data for Audit Trail: Built-in data loggers provide documentation for quality assurance.

Limitations

- Not a Substitute for Ultra-Low Freezers: Cannot store products requiring -20°C or -70°C.

- Capacity Constraints: Overstocking can block airflow and cause temperature excursions.

- Dependence on Power: Requires reliable electricity or backup systems.

- Initial Cost: Significantly more expensive than domestic refrigerators.

Safety Concerns & Warnings

- Never use a household refrigerator for vaccines or critical medications due to poor temperature uniformity and lack of alarms.

- Do not store food or beverages in medical refrigerators, as this increases door openings and contamination risk.

- Place in a well-ventilated area, away from heat sources and direct sunlight, with clearance around vents.

- Avoid “daisy-chaining” power cords or using extension cords.

- Respond immediately to alarms; have a documented emergency SOP.

Contraindications

- Should not be used in environments where ambient temperatures exceed the manufacturer’s specification (often 32°C/90°F).

- Not suitable for storing flammable chemicals unless specifically designed as explosion-proof.

- Do not use if the door seal is damaged, the alarm system is non-functional, or temperature validation fails.

5. Regulation

- FDA Class: Primarily Class II medical devices (moderate to high risk). They are 510(k) exempt in many cases but must meet general controls and performance standards.

- EU MDR Class: Typically Class IIa (medium risk).

- CDSCO Category (India): Classified as a “Medical Device.” Depending on features, usually falls under Class B (moderate-low risk).

- PMDA Notes (Japan): Regulated as a medical device. Must comply with PAL (Pharmaceutical Affairs Law) and MHLW ordinances. Products often require certification from registered certification bodies.

- ISO/IEC Standards:

- ISO 13485: Quality Management Systems for Medical Devices.

- IEC 60601-1: Safety for electrical medical equipment.

- IEC 61010-2-011: Safety requirements for refrigerating equipment.

- WHO PQS: The WHO Performance, Quality and Safety (PQS) prequalification is a gold standard for devices used in global immunization programs (E003 series for refrigerators).

6. Maintenance

- Cleaning & Sterilization: Unplug the unit. Use a mild detergent and warm water. Do not use abrasive cleaners or solvents. Wipe interior, exterior, door gasket, and shelves. Rinse and dry thoroughly. Disinfect with an approved hospital-grade disinfectant safe for surfaces. Never pour water directly into the unit.

- Reprocessing: Not applicable between uses for storage. The interior requires regular cleaning on a scheduled basis (e.g., monthly).

- Calibration: Temperature probes and displays should be calibrated annually by a qualified technician using a NIST-traceable reference thermometer. This is critical for compliance.

- Storage (When Not in Use): If decommissioned, unplug, clean thoroughly, leave the door slightly ajar to prevent mold, and store in a dry place.

7. Procurement Guide

How to Select the Device

- Assess Capacity Needs: Calculate current and future storage volume. Allow for 20-30% empty space for air circulation.

- Evaluate Environment: Consider ambient temperature, humidity, and space dimensions.

- Identify Must-Have Features: Locking doors, digital data logging, remote alarms, battery backup, glass/solid door.

- Check Compliance: Ensure it meets relevant national and international standards (WHO PQS for immunization programs).

Quality Factors

- Temperature Uniformity: Ask for validation data mapping hot/cold spots.

- Recovery Time: Faster is better.

- Alarm Reliability: Battery-backed alarms are essential.

- Build Quality: Inspect door seal strength, shelving sturdiness, and overall construction.

- Warranty & Service: Look for a minimum 3-year compressor warranty and accessible local service.

Certifications

Look for CE Marking (EU), FDA Listing, WHO PQS Pre-qualification (for public health), and ETL/UL for electrical safety.

Compatibility

Ensure it fits the designated space and that its data logging system can integrate with existing pharmacy or facility monitoring systems if required.

Typical Pricing Range

- Compact (1.7-4.5 cu. ft.): $1,000 – $2,500

- Standard (5-15 cu. ft.): $2,500 – $6,500

- Large Capacity (15+ cu. ft.): $6,500 – $15,000+

- (Prices vary widely based on features, brand, and region.)

8. Top 10 Manufacturers (Worldwide)

- Helmer Scientific (USA) – A Thermo Fisher brand. Leader in blood bank and pharmacy refrigeration. Known for i.Series and Horizon.

- PHCbi (Panasonic Healthcare) (Japan) – Renowned for reliability and innovation in biomedical storage. VIP series is industry-standard.

- Thermo Fisher Scientific (USA) – Global giant offering a wide range under brands like Forma and Revco.

- Dometic (Sweden) – Strong in mobile and modular cooling solutions for healthcare, including the MediCool line.

- Vestfrost Solutions (Denmark) – Specializes in high-efficiency, sustainable refrigeration for the healthcare sector.

- Follett Products (USA) – Known for ice and water systems, but also a player in medical refrigeration.

- Labcold (UK) – Manufacturer of a wide range of laboratory and pharmaceutical refrigerators.

- Summit (USA) – Offers commercial and medical-grade refrigerators, often seen in clinical settings.

- Dulas (UK) – Specialist in solar-powered and off-grid vaccine refrigeration for developing countries.

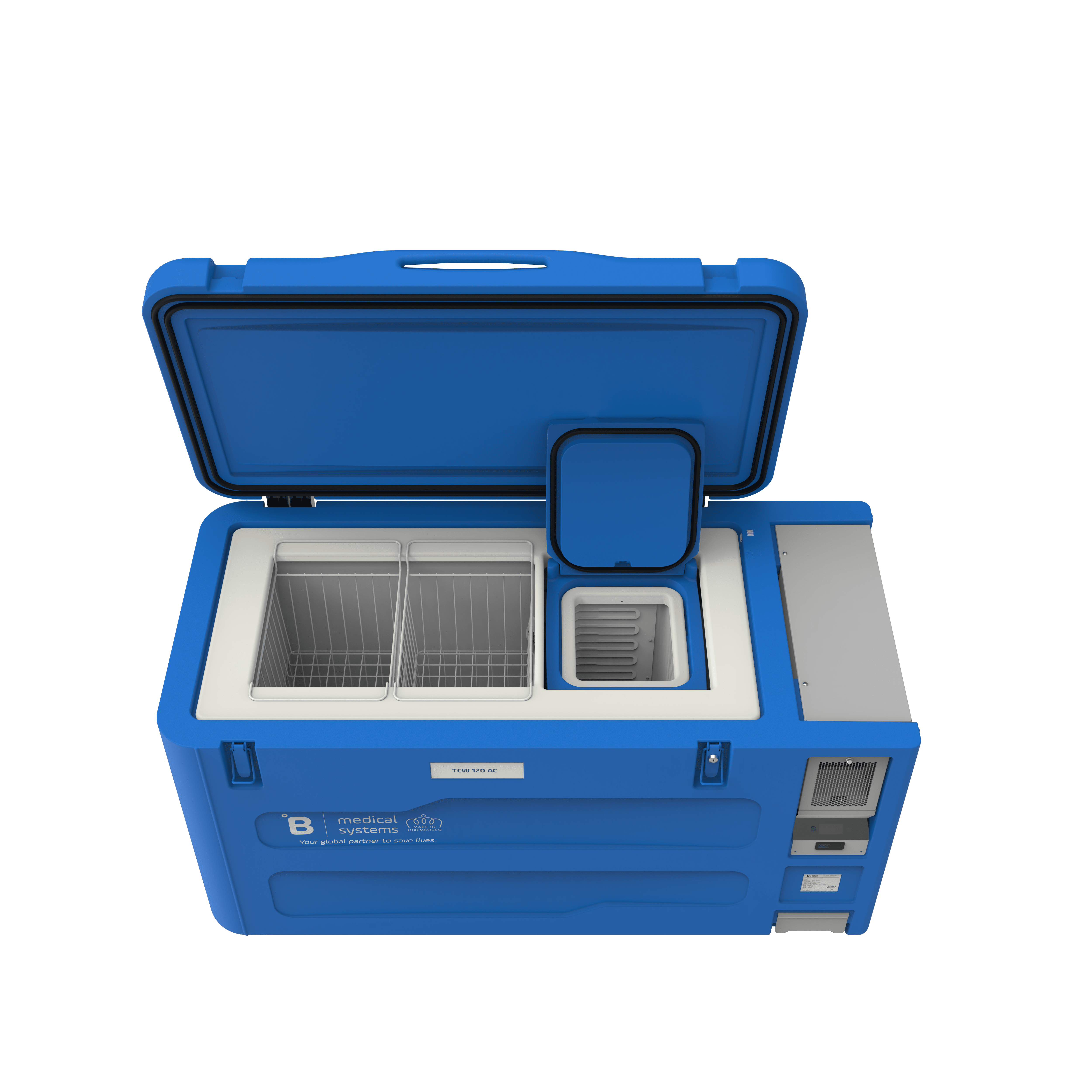

- B Medical Systems (Luxembourg) – Focused on vaccine cold chain, from transport to storage, meeting rigorous WHO standards.

9. Top 10 Exporting Countries (Latest Year – Based on HS Code 8418, Medical Refrigerators)

- China – Dominant exporter, offering a wide range from budget to high-end models.

- United States – Major exporter of high-specification, technologically advanced units.

- Germany – Renowned for precision engineering and high-quality medical devices.

- Italy – Strong in design and manufacturing of specialized medical equipment.

- Japan – Exports technologically advanced units from leaders like PHCbi.

- Denmark – Home to Vestfrost, a key player in efficient medical cooling.

- Sweden – Exports from Dometic and other specialized manufacturers.

- United Kingdom – Exports specialized laboratory and pharmacy refrigerators.

- Mexico – Growing export hub, often for North American market assembly.

- South Korea – Increasing exporter of competitively priced, quality medical devices.

10. Market Trends

- Current Global Trends: Rising demand driven by global immunization programs (e.g., HPV, COVID-19), biologics boom, and decentralization of healthcare (more clinics, pharmacies).

- New Technologies: Integration with Internet of Things (IoT) for real-time, cloud-based monitoring and predictive maintenance. Use of natural refrigerants (like R600a) for sustainability. Phase Change Material (PCM) liners for extended holdover during power outages.

- Demand Drivers: Stringent regulatory requirements, growth in personalized medicine (requiring specific storage), and increased focus on vaccine equity in low-resource settings.

- Future Insights: Expect smarter refrigerators with AI-driven analytics to predict failures and optimize energy use. Increased demand for ultra-low energy models and those designed for specific high-value drugs. The market will continue to consolidate around major players offering full cold-chain solutions.

11. Training

- Required Competency: Users must be trained on: proper loading (don’t block vents), temperature monitoring procedures, alarm response protocols, routine cleaning, and documentation. A designated person should manage data downloads and oversee maintenance.

- Common User Errors:

- Overstocking the refrigerator.

- Placing products directly in front of air vents.

- Propping the door open during restocking.

- Ignoring or silencing alarms without investigation.

- Placing temperature probes incorrectly (e.g., in door or empty air).

- Best-Practice Tips:

- Perform Daily Temperature Checks (manual or verify digital log).

- Use a validated buffer solution (glycol, glycerol, or vial) to monitor actual product temperature, not just air temperature.

- Store “Use First” boxes for products soon to expire.

- Keep a “Log Book” next to the unit for door openings, cleaning, alarms, and maintenance.

- Have a written Power Failure Plan and know where to move products in an emergency.

12. FAQs

1. Q: Can I just use a good-quality household refrigerator?

A: No. Household refrigerators have wide temperature fluctuations, cold spots (where vaccines can freeze), and lack critical alarms and data logging required for compliance.

2. Q: How often should I defrost a vaccine refrigerator?

A: Most modern medical refrigerators are auto-defrosting or have “cycle defrost” systems that prevent significant frost buildup. Manual defrosting is rarely needed if the door seal is good.

3. Q: Where should I place the temperature probe/monitor?

A: Place it in a central location, inside a validated buffer bottle or glycol-filled container that mimics the temperature of a vaccine vial. Never place it in the door, on the top shelf, or against the back wall.

4. Q: What should I do if the temperature alarm goes off?

A: Immediately check the display and contents. Do not move or discard products yet. Note the time and temperature. If it’s a brief excursion, the products are likely still viable (refer to manufacturer stability data). If the unit has failed, implement your emergency relocation plan. Contact maintenance.

5. Q: How long will vaccines stay cool during a power outage?

A: It depends on the model, ambient temperature, and how full it is. A well-stocked, well-insulated unit may hold temperature for 2-4 hours. Never open the door during an outage. Consider a unit with a battery backup for alarms and potentially for the compressor.

6. Q: How do I validate that my refrigerator is working correctly?

A: Perform a “temperature mapping” study by placing multiple data loggers throughout the empty and loaded cabinet over 24-48 hours. This identifies any hot or cold spots and verifies uniformity.

7. Q: Can I store non-medical items in a small empty space?

A: It is strongly discouraged. Any additional items increase the thermal mass, affect recovery time, and increase door-opening frequency. The space should be reserved for medical products only.

8. Q: What is the typical lifespan of a vaccine refrigerator?

A: With proper maintenance and calibration, a high-quality medical refrigerator can last 10-15 years. The compressor is often the first major component to require service.

13. Conclusion

A vaccine/medication refrigerator is far more than just a “fridge.” It is a precision medical device that serves as the guardian of temperature-sensitive, often life-saving products. Selecting the right model, installing it correctly, maintaining it rigorously, and using it with trained competence are non-negotiable responsibilities for any healthcare facility. By adhering to the guidelines and best practices outlined in this guide—from procurement based on WHO PQS standards to daily temperature monitoring—healthcare providers can ensure the integrity of their pharmaceutical cold chain, protect patient safety, comply with regulations, and avoid costly product losses. Investing in and managing this critical equipment is a fundamental pillar of effective, modern healthcare delivery.

14. References

- World Health Organization (WHO). Immunization in Practice: A practical guide for health staff. Module 2: The Vaccine Cold Chain. WHO, 2015.

- World Health Organization (WHO). PQS Performance, Quality and Safety (PQS) Catalogue – E003 Refrigerators.

- Centers for Disease Control and Prevention (CDC). Vaccine Storage and Handling Toolkit. CDC, 2023.

- U.S. Food and Drug Administration (FDA). Code of Federal Regulations Title 21, Part 880 – General Hospital and Personal Use Devices.

- International Electrotechnical Commission (IEC). IEC 61010-2-011:2019 Safety requirements for electrical equipment for measurement, control, and laboratory use – Part 2-011: Particular requirements for refrigerating equipment.

- PDA Technical Report No. 58 (TR 58): Risk Management for Temperature-Controlled Distribution. Parenteral Drug Association, 2012.

- European Medicines Agency (EMA). Guideline on good distribution practice of medicinal products for human use (2013/C 343/01).